In high-temperature industrial settings, sealing solutions must withstand extreme pressure, heat, and chemical exposure to ensure operational safety and durability. Stainless steel-reinforced graphite seals are designed precisely for these conditions, offering exceptional performance in demanding environments. Their resilience makes them vital in industries like energy, oil and gas, and heavy machinery.

What Are Stainless Steel-Reinforced Graphite Seals?

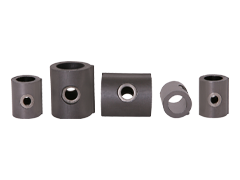

Stainless steel-reinforced graphite seals combine flexible graphite with a stainless steel layer to deliver superior thermal resistance, chemical stability, and mechanical strength. This design ensures the seal remains intact under fluctuating pressures and temperatures, outperforming conventional gaskets in demanding conditions. Its reinforced structure also resists oxidation and creep, providing extended service life and lower maintenance needs.

Meet the Stars: AB12 and AB18 Seal Grades

At South Eastern Gaskets, we are proud to offer two distinguished grades of stainless steel-reinforced graphite seals: AB12 and AB18. Both are expertly designed to deliver premium performance, with nuanced differences that suit specific application requirements.

AB12: Balanced Durability for Broad Applications

AB12 is a versatile sealing grade made from pure graphite and reinforced with a precision-engineered stainless-steel eyelet. This combination delivers outstanding sealing performance and thermal resistance, making it ideal for demanding industrial applications.

Key Benefits:

• Excellent sealing capability under pressure

• High thermal resistance for moderate to high-temperature environments

• Strong chemical resistance for harsh operating conditions

• Cost-effective solution without compromising performance

• Durable construction with stainless steel reinforcement

Ideal Applications:

• Manufacturing operations

• Power generation systems

• Process engineering environments

• Standard flanged connections

• Dynamic sealing systems

AB18: Engineered for the Extreme

For operations that demand maximum endurance in the harshest environments, AB18 is the ideal choice. Made from pure graphite and reinforced with a stainless-steel eyelet, it is specifically engineered for extreme heat and high-pressure applications.

Key Advantages:

• Designed for extreme temperature and pressure conditions

• Excellent resistance to corrosive agents and mechanical stress

• Proven performance under rapid thermal cycling

• Reliable sealing where failure is not an option

Common Applications:

• Refineries and petrochemical plants

• Jet propulsion systems

• High-performance engines and turbines

• Critical sealing zones in heavy industrial operations

Applications of Stainless Steel-Reinforced Graphite Seals

Thanks to their robust construction and superior performance, stainless steel-reinforced graphite seals are widely used across multiple industries. Their application range includes:

• Boilers and Steam Systems

• Power Plants

• Oil & Gas Industry

• Automotive and Heavy Equipment

• Aerospace

• Metal and Glass Manufacturing

Durable Gasket Solutions for Demanding Industries

South Eastern Gaskets is a family-owned Australian manufacturer with 50+ years of experience in high-quality, custom sealing products like stainless steel-reinforced graphite seals. We offer trusted, durable solutions for demanding industrial applications, including options like AB12 for versatility and AB18 for extreme heat resistance. Our expert team is dedicated to helping clients nationwide select cost-effective, long-lasting products backed by deep industry knowledge and personalised support.

Explore our full range of products and discover why we are the preferred sealing supplier across Australia.