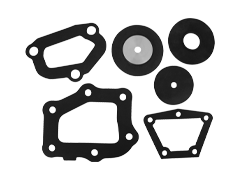

Corr-a-seal Gaskets for Sale: Certified Fire Safe Solutions for Critical Industrial Applications

Corr-a-seal Gaskets for sale from South Eastern Gaskets—certified fire-safe solutions designed for critical industrial applications across key sectors. Corr-a-seal gaskets...