South Eastern Gaskets Capabilities

At South Eastern Gaskets, we are committed to staying at the forefront of technology in the industry. Hence, we invest in advanced equipment and training to carry out processes that can yield a diverse range of products from various materials for our customers.

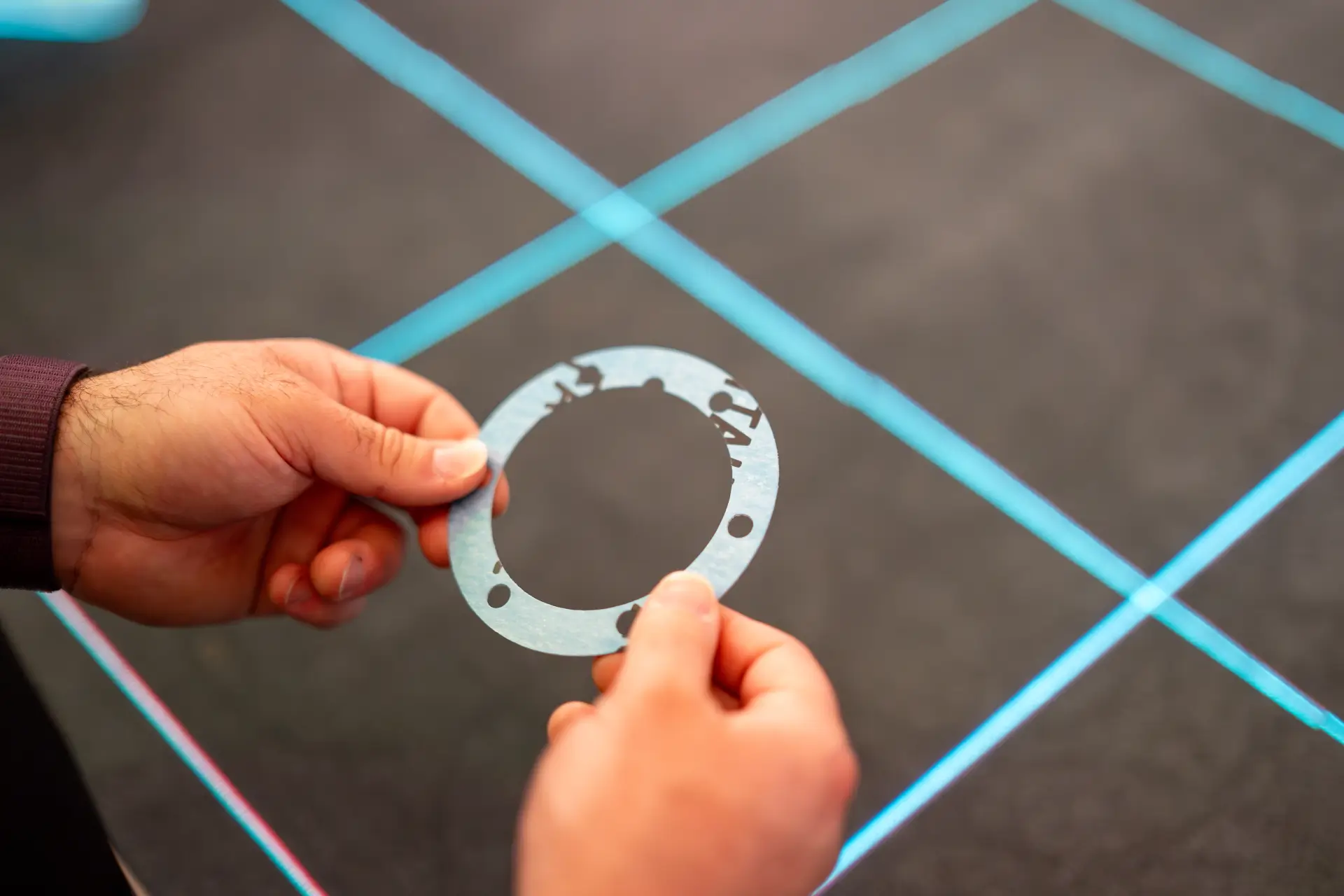

CNC Cutting

We have been using state-of-the-art CNC knife cutting tables since 2006, and now have a range of 7 cutting tables, all with various capabilities which has allowed us to diversify the range in which we can cut.

Our CNC tables can produce difficult shapes without the need for tooling. All we need is a customer- approved drawing or a PDF file that can be emailed by our customers, reducing set-up costs and improving turn-around time. Our CNC tables are also superior when it comes to cutting tang graphite, which can provide a smooth and clean cut.

CNC Milling/ Routing

One of the more recent additions to our CNC table range also has milling and routing capabilities. With this addition, we can now easily cut a wide range of plastics, non-ferrous metals and thicker foams and rubber materials.

It also has the capability to add chamfers, steps, pockets and other various three-dimensional cuts.

Rubber Moulding/ Vulcanising

We are also equipped with two compression moulding presses. We manufacture a wide range of rubber moulded products with these presses out of EPDM, silicone and nitrile rubber to accommodate various industries and applications. These presses also allow us to vulcanise rubber to metal, and rubber to rubber. We create custom sleeves and flexible joins with this process as well as various seals from extrusions and O-rings.

Washer stamping

Another area in which South Eastern Gaskets excels is high-volume washer stamping. We have 6 high speed mechanical presses all in different sizes to accommodate a range of washer sizes and materials. We stamp washers from various metals, composites, fibres and rubber materials.

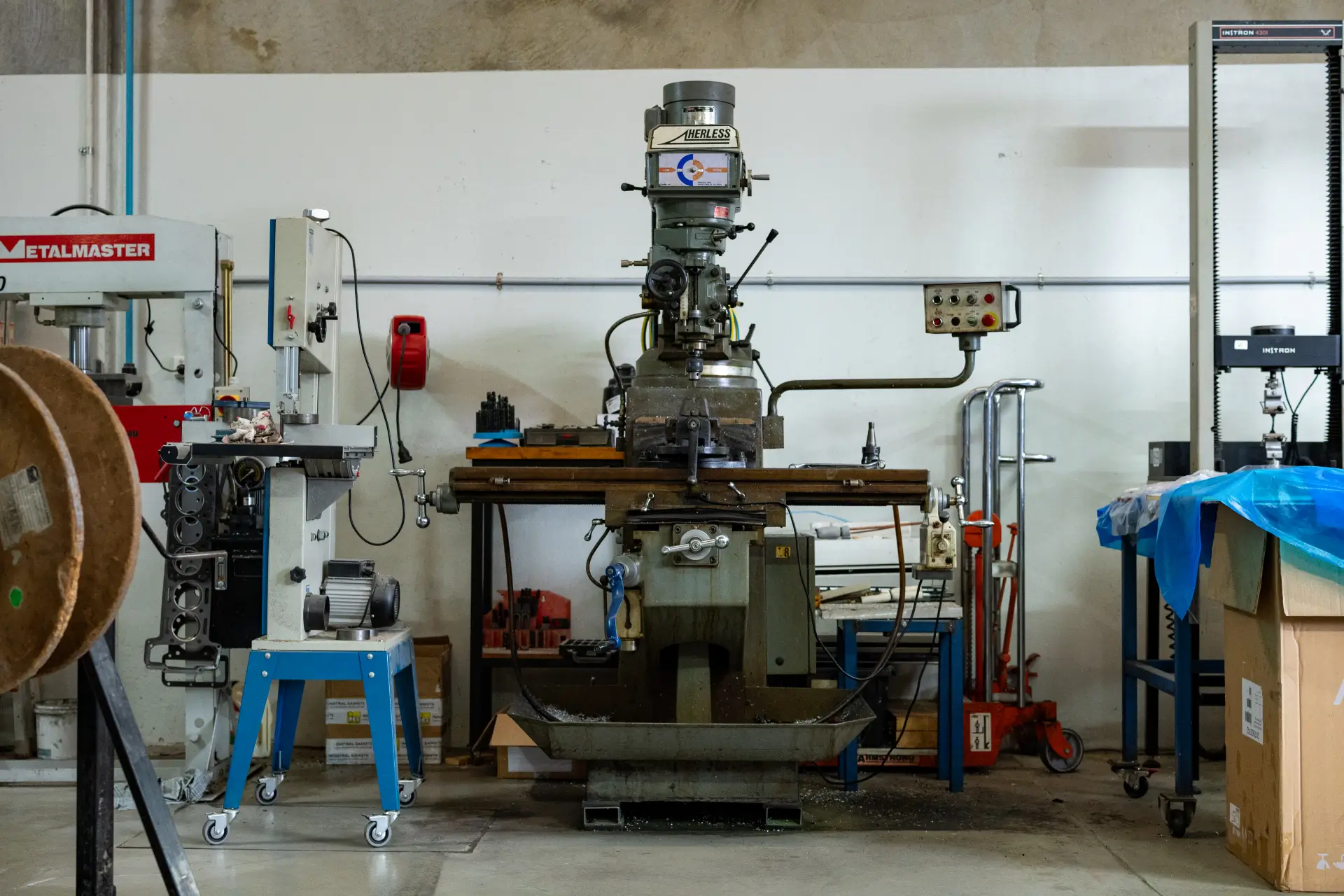

Tool Room

To maintain our high level of quality, we are equipped with our own tool room to make our own washer dies and moulding tools. This allows us to keep costs and lead times down while maintaining quality.

Fabrication

There are times when certain parts require additional processes, whether that is joining larger gaskets, applying adhesive backings or tapes, joining different materials together, or any other process that may be required. South Eastern Gaskets has decades of experience in additional fabrication processes and we are always open to helping our customers with any potential requirement.

Laser Kiss Cutting machine

The most recent addition to our machine catalogue is a laser kiss-cutting machine. This machine gives us the ability to cut various tapes that struggle to cut by normal means. It is ideal for higher volume quantities, as it can leave the part on the backing paper while weeding off the excess material that is not required. Reach out and find out how this machine can assist you with your manufacturing lines.

Contact us today to experience the professionalism and experience of a company that prides itself on producing quality parts for all industries.