Obtain a high-quality industrial gasket supply in VIC and SA from South Eastern Gaskets. Learn how our CNC machining optimises the gasket manufacturing process.

CNC machining has revolutionised gasket manufacturing by providing unmatched precision, efficient production speeds, and easy customisation. As long as they are carried out by professionals in the field, these advanced processes can ensure that each gasket meets exact specifications, reducing waste and enhancing performance.

What to Look for in an Industrial Gasket Supply?

To gain access to high-quality industrial gaskets, you should opt for a reliable gasket supplier. Some characteristics of a good industrial gasket supplier are as follows.

1. Technical Expertise: A good supplier has knowledgeable staff who can advise on gasket materials, designs, and installation based on your industrial needs. Their expertise is invaluable in recommending the best gaskets for your application and ensuring optimal performance.

2. Proven Industry Experience: A reliable supplier also has industry-specific knowledge to ensure they understand the demands of your applications and can provide tailored solutions.

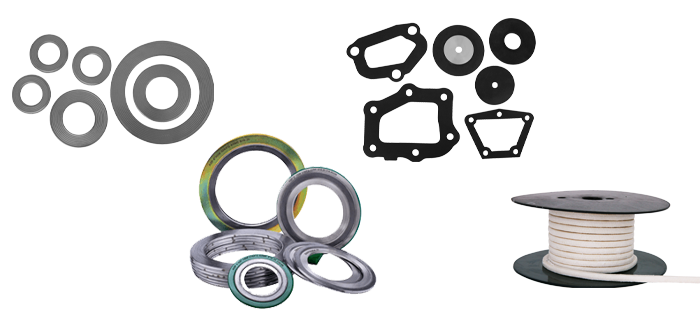

3. Material Variety and Customisation Options: A good supplier should offer a range of materials, like rubber, PTFE, graphite, and metal, to suit different applications. Customisation capabilities for unique shapes, sizes, and specifications are also essential.

4. Fast Lead Times and Reliable Delivery: Fast lead times and on-time delivery are vital to minimise downtime in your operations. A good supplier has efficient production capabilities and dependable logistics to meet urgent and ongoing demands.

5. Quality Assurance and Standards Compliance: A respectable supplier meets industry standards (such as ISO certifications) and has quality control processes in place. Quality assurance means their gaskets are durable, precise, and built to meet your application requirements.

CNC Machining Optimises Gasket Manufacturing

If you want to get an industrial gasket supply quickly and cost-efficiently, then you should opt for a supplier that has CNC machining capabilities, and South Eastern Gaskets is your trusted supplier and manufacturer of industrial gaskets with CNC capabilities. We carry out gasket manufacturing processes with the help of CNC machines. Some things you can expect from our CNC machining capabilities are as follows.

• Enhanced Precision and Accuracy: CNC machining allows for highly precise cuts and intricate shapes, even for complex gasket designs.

• Fast Production Times: CNC machines automate and streamline the cutting process, enabling rapid production without compromising accuracy.

• Flexibility in Material Handling: CNC machining is compatible with a wide range of gasket materials, such as rubber, graphite, PTFE, and metal.

• Consistency Across High Volumes: CNC machines produce identical gaskets with minimal variation, even in large quantities.

• Customisation for Specialised Applications: CNC technology allows for easy customisation, enabling the production of unique gasket shapes and sizes tailored to specific machinery.

• Reduced Material Waste: CNC machining maximises material usage by cutting exactly to specifications, reducing waste from off-cuts and misaligned cuts.

• Automated Quality Control: Many CNC systems have integrated quality control features that detect any deviations during production, maintaining high standards.

• Ease of Design Adjustments: CNC machining is ideal for prototyping new gasket designs, as digital files can be quickly adjusted and reproduced

Some CNC machining processes we carry out for manufacturing sealing solutions are CNC cutting and CNC milling/routing. Contact us to maximise high-quality industrial gaskets and other sealing solutions for your needs.