Compare API 607 and ISO 10497 standards for fire-safe sealing. Learn key differences and trust South Eastern Gaskets for reliable sealing solutions.

Industrial systems dealing with flammable or high-pressure materials demand absolute safety. Fire-safe sealing plays a crucial role in preventing leaks and protecting equipment under extreme conditions. Understanding the differences between API 607 and ISO 10497 helps engineers choose the right sealing solution for their projects.

Understanding Fire-Safe Sealing and Its Importance

Fire-safe sealing is the ability of valves, gaskets, or sealing assemblies to maintain pressure integrity during and after exposure to fire. This capability is crucial in industries like oil and gas, petrochemicals, and energy, where safety and asset protection are paramount. Unlike traditional seals that can degrade under extreme heat, fire-safe designs are built to withstand flames and prevent hazardous leaks or explosions.

At South Eastern Gaskets, we understand the Australian industry’s demand for seals that perform under pressure. Our products comply with the highest standards — giving engineers peace of mind knowing their systems are both safe and compliant.

API 607: The Core of Reliable Fire-Safe Sealing Practices

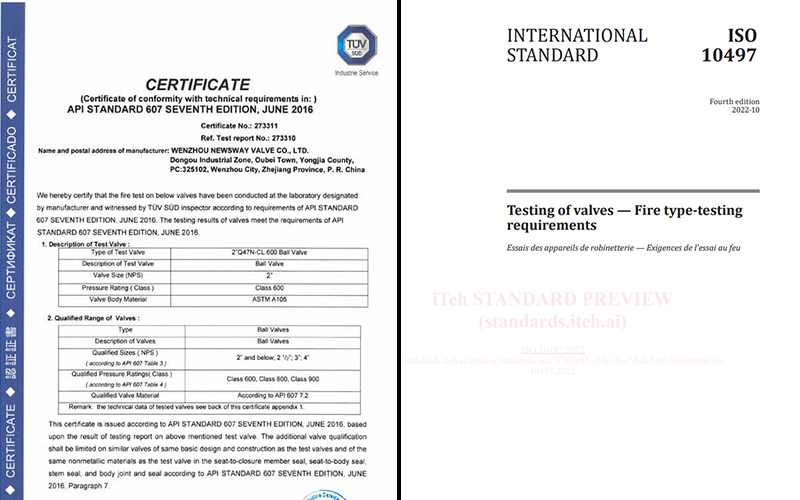

The API 607 standard is widely recognised in the oil and gas industry. It specifies fire testing requirements for quarter-turn valves equipped with resilient seats. The latest edition (7th) also applies to valves made with graphite or other fire-safe sealing materials.

Here’s what API 607 typically evaluates:

• Fire Exposure – The valve is exposed to a controlled flame for a specific period while maintaining internal pressure.

• Leakage Measurement – Tests are conducted before, during, and after the fire to ensure minimal leakage.

• Operational Capability – After the fire test, the valve must still operate and provide a tight shutoff.

• Cooling Cycle Performance – Valves are cooled and re-tested to verify ongoing performance after thermal shock.

ISO 10497: The International Equivalent

The ISO 10497 standard was created to establish a globally recognised fire test for valves. Although it shares the same purpose as API 607, its methodology and scope vary slightly. It applies to all valve types and provides detailed guidelines for testing equipment, temperature control, and pressure measurement.

Key differences include:

• Broader Scope: Covers all valve types rather than just quarter-turn designs.

• Temperature Range: Specifies more detailed control of flame temperature and duration.

• Test Setup: Provides flexibility in test apparatus, allowing for broader international use.

Choosing the Right Standard: Practical Considerations for Engineers

When deciding which standard to follow, engineers should assess the specific application, regulatory environment, and customer requirements.

Here are a few practical tips to guide your decision:

• Industry Norms: Oil and gas projects typically favour API 607, while international EPC projects may require ISO 10497.

• Valve Type: If you’re working beyond quarter-turn valves, ISO 10497 may be more applicable.

• Geographic Scope: Australian industries often accept both standards, but project specifications usually dictate which to use.

• Supplier Expertise: Partner with a supplier that understands both standards and can advise on the best sealing solutions.

Experience Fire-Safe Excellence with South Eastern Gaskets

In high-risk industries, every seal matters when it comes to safety and reliability. South Eastern Gaskets is trusted across Australia for delivering precision, compliance, and quality. Along with our expertise in fire-safe sealing, we deliver high-quality sealing products that meet or exceed API and ISO standards to keep your operations safe and efficient.

Contact us today to learn how we can support your next project with high-performance sealing solutions you can trust.

Related Blog Articles:

Sealing Rubber Gaskets: Choose the Right Seal for Water, Oil, or Chemical Resistance

Stainless Steel-Reinforced Graphite Seals: AB12 & AB18 for Extreme Heat