South Eastern Gaskets provides high-temperature gaskets for boilers and furnaces, offering durable, heat-resistant sealing solutions.

High-temperature gaskets play a crucial role in industrial applications, ensuring reliable sealing in extreme heat environments. These specialised gaskets prevent leaks, maintain efficiency, and enhance the safety of high-temperature systems such as boilers and furnaces. Designed to withstand extreme heat and pressure, these gaskets are crucial in industries like power generation, manufacturing, and processing, ensuring durability and efficiency.

Applications in Boilers

Boiler systems operate under extreme conditions, including high-pressure steam and elevated temperatures. Effective sealing is crucial to prevent leaks, enhance operational safety, and prolong equipment lifespan. South Eastern Gaskets provides specialized high-temperature boiler gaskets designed for durability, reliability, and efficiency under harsh boiler conditions.

• AB12 & AB18 Boiler Gaskets – AB12 & AB18 boiler gaskets are engineered specifically for sealing boilers exposed to high pressures and temperatures. Manufactured using robust, heat-resistant materials, these gaskets deliver excellent sealing performance, effectively preventing steam and gas leaks. Their superior durability reduces maintenance, minimizes downtime, and enhances overall operational efficiency.

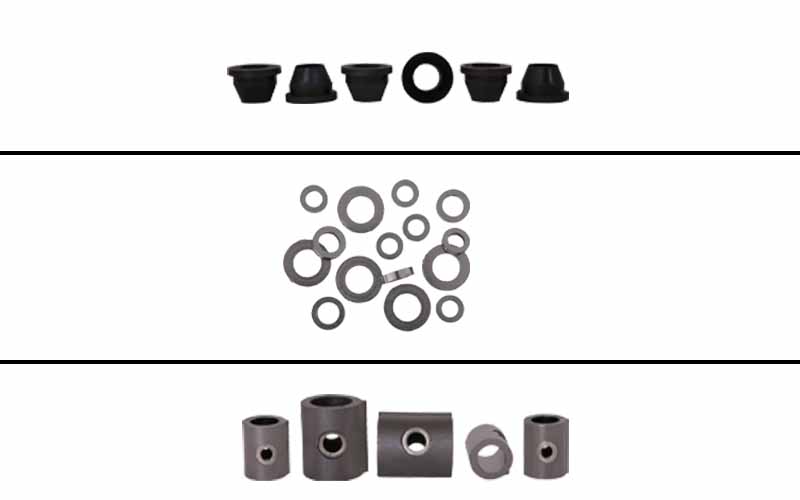

• Dieform Graphite Rings – Dieform graphite rings are essential gaskets for boiler applications due to their exceptional thermal conductivity, oxidation resistance, and sealing integrity under high-pressure conditions. Ideal for demanding industrial boiler environments, graphite rings provide reliable, long-lasting seals that optimise boiler performance and safety.

• Rubber Cone Gaskets – Rubber cone gaskets are flexible, durable, and highly heat-resistant, making them ideal for boiler sealing applications. Their excellent sealing capabilities effectively prevent steam leaks, contributing to improved boiler efficiency, reduced maintenance requirements, and increased reliability in demanding high-temperature environments.

Applications in Furnaces

Industrial furnaces operate continuously at extremely high temperatures, making reliable sealing solutions essential for efficiency, safety, and longevity. High-temperature furnace gaskets from South Eastern Gaskets are engineered specifically to withstand intense heat, thermal cycling, and harsh operating environments, ensuring system integrity and preventing heat loss.

• Graphite-based Furnace Gaskets – Graphite-based gaskets are an ideal sealing solution for industrial furnaces due to their exceptional heat resistance, flexibility, and chemical stability. Capable of enduring extreme temperatures without degradation, these gaskets effectively seal furnace doors, flanges, and joints. Their excellent chemical resistance further ensures reliability in high-temperature processing applications, extending equipment lifespan and reducing maintenance costs.

• Metal-reinforced Furnace Gaskets – Metal-reinforced gaskets provide enhanced strength, durability, and resilience, making them well-suited for high-pressure furnace sealing applications. By combining the structural strength of metal with the sealing properties of high-performance gasket materials, these reinforced gaskets ensure long-term reliability and consistent performance in heavy-duty industrial furnaces, minimizing downtime and improving operational efficiency.

Reliable High-Temperature Gaskets for Superior Sealing Solutions

Ensuring the safety, efficiency, and longevity of boilers and furnaces requires the right high-temperature gaskets. South Eastern Gaskets provides a wide range of high-quality gaskets, seals, and washers, including custom-made options for diverse industrial applications. Our expert guidance, delivery services, and onsite visits help clients find the most suitable gasket solutions.

Explore our extensive product range to find the best high-temperature sealing solutions for your industry. Visit our product page here: South Eastern Gaskets products.

For more detailed insights into gasket performance under high-temperature conditions, refer to Garlock’s comprehensive article, “Gaskets Designed to Take the Heat”.