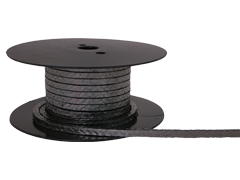

Industrial sealing solutions must perform under the most demanding conditions, from extreme temperatures to high pressures and aggressive chemicals. Among the most reliable and efficient options available today is MP8005 Graphite Yarn Packing, a product designed to meet the highest standards of endurance and versatility. Its innovative construction makes it an ideal choice across a wide range of industries, offering exceptional performance where ordinary sealing materials fail.

Advanced Material Composition for Extreme Conditions

The foundation of the MP8005 Graphite Yarn Packing lies in its carefully engineered graphite yarns, reinforced with an Inconel wire or similar metallic reinforcement. This combination provides exceptional resilience, enabling the packing to maintain its integrity even when subjected to high mechanical stress, thermal cycling, and chemical exposure.

Graphite’s exceptional thermal conductivity and lubricity enable efficient heat dissipation while minimising friction, reducing wear and extending equipment life. It maintains reliable sealing performance in valves, pumps, and expansion joints without hardening or oxidising over time. Resistant to chemicals, oils, steam, and solvents, it offers exceptional versatility across power, petrochemical, and marine industries.

For a deeper dive into the properties and uses of graphite, check out this informative resource from Wikipedia.

Key Advantages and Industrial Applications

What sets this graphite yarn packing apart is its combination of strength, flexibility, and adaptability. It caters to industries that demand superior sealing reliability and long-term operational efficiency. Some key advantages include:

• Exceptional Heat Resistance: Capable of withstanding temperatures exceeding 450°C in oxidising atmospheres and over 2000°C in non-oxidising environments.

• Low Friction and Smooth Operation: Reduces wear on shafts and housings, enhancing the longevity of mechanical systems.

• Chemical Inertness: Compatible with most industrial fluids, including acids, alkalis, and hydrocarbons.

• Pressure Resilience: Performs effectively under both high and fluctuating pressures without losing sealing integrity.

• Reduced Maintenance Costs: Long service life means fewer shutdowns and lower replacement expenses.

Why Engineers and Maintenance Teams Prefer SE Gaskets

When selecting industrial sealing products, choosing a trusted supplier is just as critical as the material itself. SE Gaskets is a leading name in the Australian sealing industry, offering premium-grade solutions designed for performance, durability, and compliance with global standards.

At SE Gaskets, we provide high-quality solutions like MP8005 Graphite Yarn Packing, engineered for precision and reliable performance in any application. Our experts provide guidance to help engineers and maintenance teams improve sealing efficiency, reduce downtime, and extend equipment life. We also offer a wide range of sealing products, including gasket sheets, O-rings, jointing materials, and custom cut solutions, backed by our commitment to quality and excellence.

Confidence in Every Seal with MP8005 Graphite Yarn Packing

We pride ourselves on delivering innovative, high-quality sealing solutions that stand the test of time. The MP8005 Graphite Yarn Packing exemplifies our dedication to offering products that combine advanced materials with superior engineering.

Explore our full range of gasket and packing solutions on our product page or contact our expert team today to discuss how we can enhance the performance and reliability of your sealing systems.

Related Blog Articles:

The Advantages of Ordering Industrial Gaskets Direct from a Local Australian Manufacturer

Dieform Graphite Rings for Sale: Premium Industrial-Grade Carbon Sealing Solutions